Nestled in one small work stall littered with the soldering irons, tools, and gizmos you’d expect to find at the personal craft desk for one of many projects in the cavernous expanse and labyrinthine maker-movement beehive in Somerville, Jeremy Fryer-Biggs is a knife-industry disruptor hard at work.

The University of Chicago and Tufts University graduate is set up in a mad genius’s enclave in the back of Artisan’s Asylum, where he tinkers and improves upon NextGen Knives, a Kickstarter project he’s behind billed as “the next evolution in cutlery design.”

“The knife industry is all about tradition,” he says. “But when technology advances it’s important to do an audit and ask, ‘Have things changed?’ I love cooking, and every chef I’d ever met in my life had these hand calluses. That means maybe there was something wrong with the design of the knives. So I started thinking about how someone could design a knife better. A year [later] and now we’re here.”

This isn’t some weekend-warrior arts and crafts project, either. Fryer-Biggs, long a builder and curious mind, got interested in prototyping during his time working on rigs and build teams for Mythbusters. He got the job after firing an email off to the well-mustachioed cohost Jamie Hyneman, who he later worked with building medic combat-training prototypes for the US military. By the time he moved on, finished graduate school at Tufts, and started his own prototyping company, he realized he could focus on creating things that could benefit people and get paid to do it.

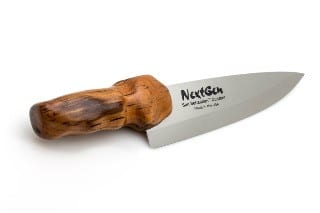

More often than not, knives have the same handle shape to them, and yet not all knives serve the same function. So to gather data on what would make a more perfect knife handle, Fryer-Biggs and his team created clay armatures around the base of the blade on the demo knives they had created using a super hard patented steel he and a partnering steel company created called NextSteel, and handed them off to chefs they knew (like Stacy Cogswell of Liquid Art House, among several others). “We said, ‘Work with it, rock with it for an hour, and then let me see what it looks like.’”

From there they took that data and created a shape built around the way you’re supposed to hold a knife between your thumb and forefinger in order to support the normally empty negative space in between someone’s hand and the handle, creating an 80/20 model using food- and medical-grade dishwasher safe silicon in the now-patented NextGrip.

“It’s basically the general geometry and generic feel to most hands,” he says. “All that research yielded this kind of grip.” Part of the patent involves the construction of the steel handle with a hole cut into the steel at the hilt in order for the molding to seal around the base, rather than being a flap of material that would peel back and fall off over time. And it’s from here things get really interesting: Chefs (or anyone) can send in a flat-scanned image of the palm of their hand, which Fryer-Biggs and his team then take and create a 3D model of to create a 100 percent custom teak handle that will be only truly functional and comfortable to the person it was created for.

At present you can pre-order one of the general base model handles for $99, and Fryer-Biggs says that if things take off there is a whole line of knives in the works. And all of them will be anchored by their obsession with handle perfection.

“They’re a reflection on who actually uses [them],” he says. “One of the things I get from chefs a lot is when you’re working in a kitchen, your knives get stolen. So this not only makes your job easier as a chef, but no one else can use it as it will feel like shit to them. And if there’s any question about whose knife it is, your handprint is laser etched onto the handle.”

“They’re a reflection on who actually uses [them],” he says. “One of the things I get from chefs a lot is when you’re working in a kitchen, your knives get stolen. So this not only makes your job easier as a chef, but no one else can use it as it will feel like shit to them. And if there’s any question about whose knife it is, your handprint is laser etched onto the handle.”

NEXTGEN KNIVES. FOR MORE INFORMATION AND THEIR KICKSTARTER PLATFORM CHECK OUT NEXTGENKNIVES.COM

Dan is a freelance journalist and has written for publications including Vice, Esquire, the Daily Beast, Fast Company, Pacific Standard, MEL, Leafly, Thrillist, and DigBoston.